CLST®: The strong, sustainable, alternative to Gen 1 mass timber.

USA 2022

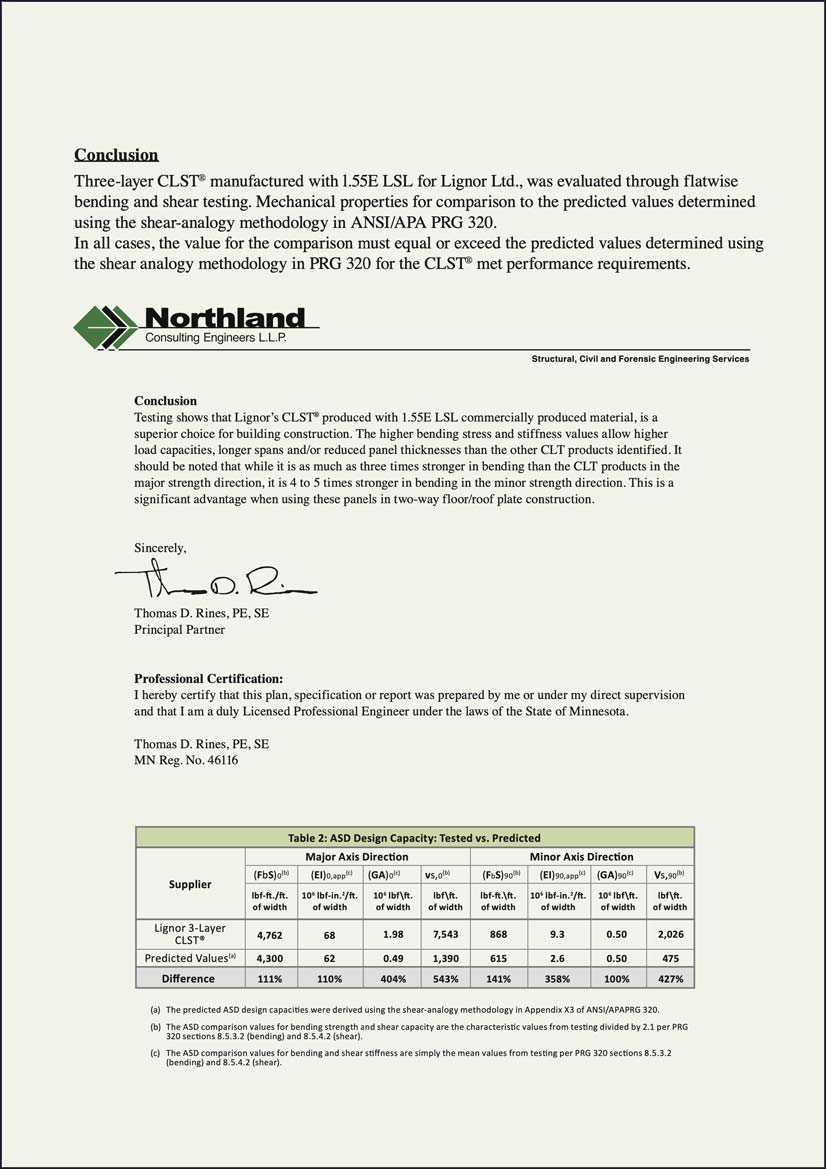

CLST® has successfully completed testing, and was analysed by Northland Engineers who provided their report stating outstanding performance results.

See this PDF file for all the details.

CLST® from Aspen has been independently proven to be up to 3 times stronger in the major axis and up to 5 times stronger in the minor axis than commercially available CLT in the U.S.

Laminae used in CLST® are treated holistically for termite, moisture, fungal and fire resistance, unlike the envelope treatment of planks used in CLT.

Lignor’s Aspen CLST® has been proven to have far lower risk of delamination in fire, unlike conventional CLT which can produce chimney effects which further fuel fires.

CLST® has superior fastener performance and holding strength when compared to conventional softwood CLT.

It is strong and lightweight, with high ductility which makes it ideal for building in earthquake zones.

Unlike LVL and plywood, it can be sawn, routed, profiled, turned, milled, nailed or screwed in any plane.

It is available in thick and thin formats.

Thin CLST®

Made with laminae thinner than 16mm has multiple applications in the transport sector, in commercial and industrial construction and for use in domestic housing as an alternative to OSB. and plywood.

Suitability:

Truck, railway wagon and bus floors

Container floors

Industrial flooring

Roofing and flooring panels/cassettes in domestic housing

Concrete shuttering boards

An alternative to plywood

An alternative to LVL

Thick CLST®

Thick CLST® with laminae thicker than 16 mm is designed to be a lower cost and better performing alternative to CLT, for use in mass panels in large structures and concrete slabs.

Suitability:

Construction of domestic housing, multi-storey apartment and industrial buildings, and warehouses.

Self-supporting roofing and flooring panels

Low-cost housing supplied in “flat pack” form

Posts and beams cut to order from large billets

“Preventing deforestation is potentially one of the simplest ways to reduce global emissions. At the moment, carbon emissions from deforestation account for some 18% of global greenhouse-gas emissions, more than all the world’s trains, cars, lorries, aeroplanes and ships combined.”

According to The Economist:

Last Gasp of the Forest, 26 Sep 2009

ESB®

ESB® or Engineered Strand Board is a eucalyptus-based Engineered Strand Board with up to twice the stiffness of softwood and superior bi-directional strength.

Suitability:

Container flooring

Concrete formwork

Industrial flooring

Base for veneered furniture

Facing material for Structural Insulated Panels in housing

“Lignor’s Cross Laminated Strand Lumber (CLST) product would be a strong competitor to regular CLT”

Senior Chair Professor Frank Lam Ph.D, P.Eng, FIWSc, FIAWS,

University of British Columbia.

The Wood Building Design and Construction,

Department of Wood Science.

2021.09.12

ESL®

ESL® or eucalyptus-based Engineered Strand Lumber has up to twice the stiffness of softwood and performs exactly the same as sawn timber.

Suitability:

Posts and beams cut to order from large billets

Industrial flooring

Manufacture of CLST™

LST®

LST® or Laminated Strand Timber (LST®) is made by laminating layers longitudinally to make beam members larger than the original press.

Suitability:

Posts and beams

Buildings requiring longer spans