The World is at a tipping point with global emissions of meeting the UN target of maximum 1.5°C temperature rise now highly unlikely according to one of the World’s leading climatologists Prof Hans Joachim Schellnhuber.

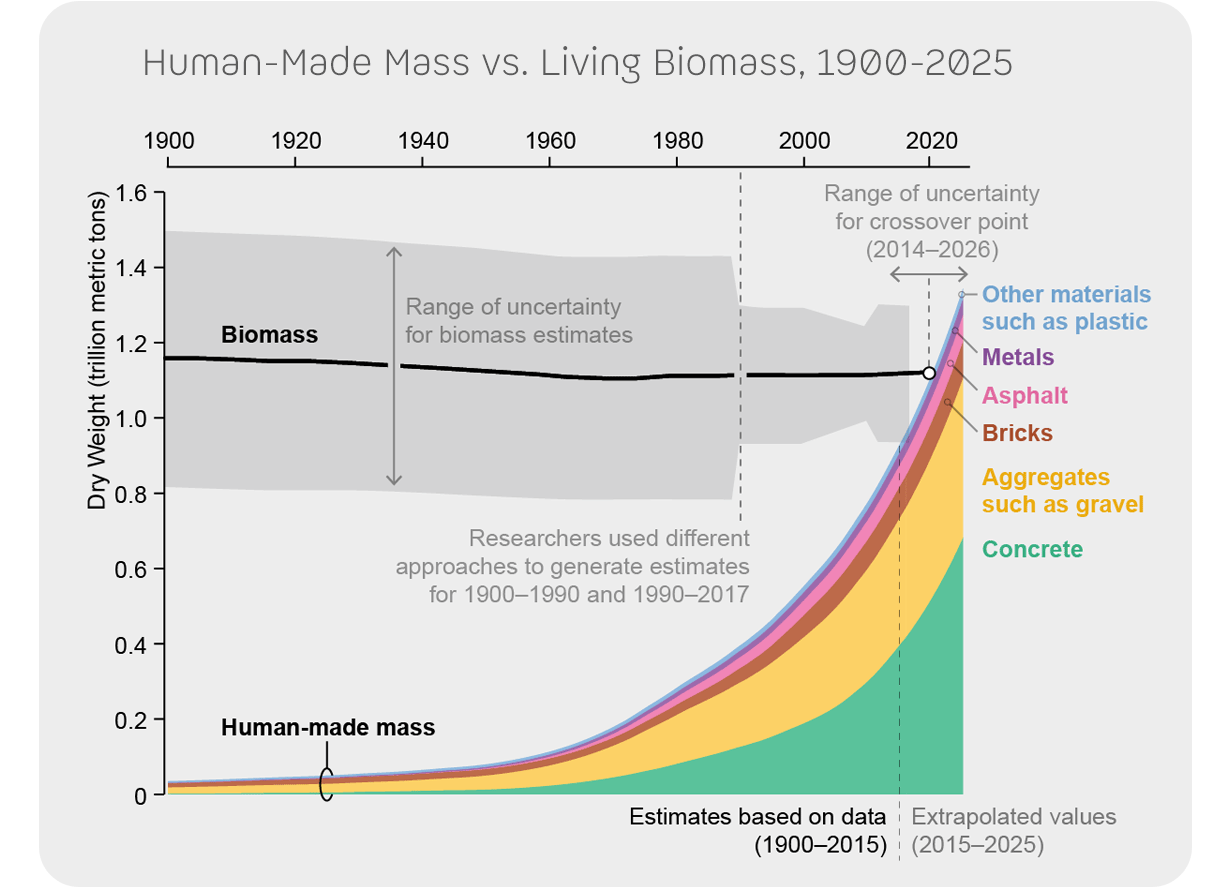

He already believes our best hope is 2°C. The total amount of anthropogenic mass (concrete, metals, aggregates, plastics) surpassed the total mass of biomass on the planet in later stages of the past decade.

Credit: Amanda Montañez; Source: “Global Human-Made Mass Exceeds All Living Biomass,” by Emily Elhacham et al., in Nature. Published online December 9, 2020

Prof. Schellnhuber sends a very clear message to the World and that is we need to dramatically shift from conventional concrete and steel construction to carbon sequestering materials like wood and other biomass. Continuing to construct the World’s new building stock at a rate of 90% in concrete and steel will lead to a total CO2 emission level of 71GT by 2050 whereas shifting to wood and biomass-based construction materials at a rate of 90%, the total amount of stored CO2 would amount to 75GT with a total emission of combined wood, steel, and concrete only 35GT.

The opportunities to have significant impact on reducing the CO2 emissions and locking it away in the built environment are great, however there are major counterforces limiting this due to the need to dramatically increase the amount of planted biomass such as trees to provide the future sustainable supply of materials. The technology developed by Lignor is at the forefront of addressing this major challenge.

Most of the mass timber produced today is sourced from larger softwood trees typically growing to an age of 80 years before harvesting. Many environmental NGOs are rightfully seeking to dramatically increase the planting of new forests but at the same time also reduce the utilisation of forests as source for the products we need. Lignor has developed a technological solution to address the challenge through utilisation of faster growth rotation tree species such as Eucalyptus, Aspen and other plantation wood species which can be harvested in a normal rotation of between 8-15 years.

In Brazil Eucalyptus can grow up to 90m3/Ha p.a. whereas pine in NZ grows at about 30m3/Ha p.a. Similarly a good Scandinavian Boreal forest grows at 5m3/Ha p.a. whereas young Aspen grows up to 22m3/Ha p.a. This means that logs which have traditionally been used in paper production can now be used far more efficiently to provide Lignor’s patented Engineered Strand Lumber (ESL®) in Eucalyptus and Orientated Strand Lumber (OSL) in other species. ESL®, OSL and mass timber products such as Lignor patented CLST® to support the urgent need to replace concrete and steel with wood in the built environment. The net result of this is a significant increase in the potential available wood resource from sustainably managed forestry plantations to lock away the sequestered CO2 within a self-sustaining industrial symbiosis.

“There is approximately 20,000,000 ha of eucalyptus plantations in some 86 countries planted primarily for pulp and paper. (Ref FAO) Much of this is under utilised as we move away from newspapers and books with increasing use of screen reading.”

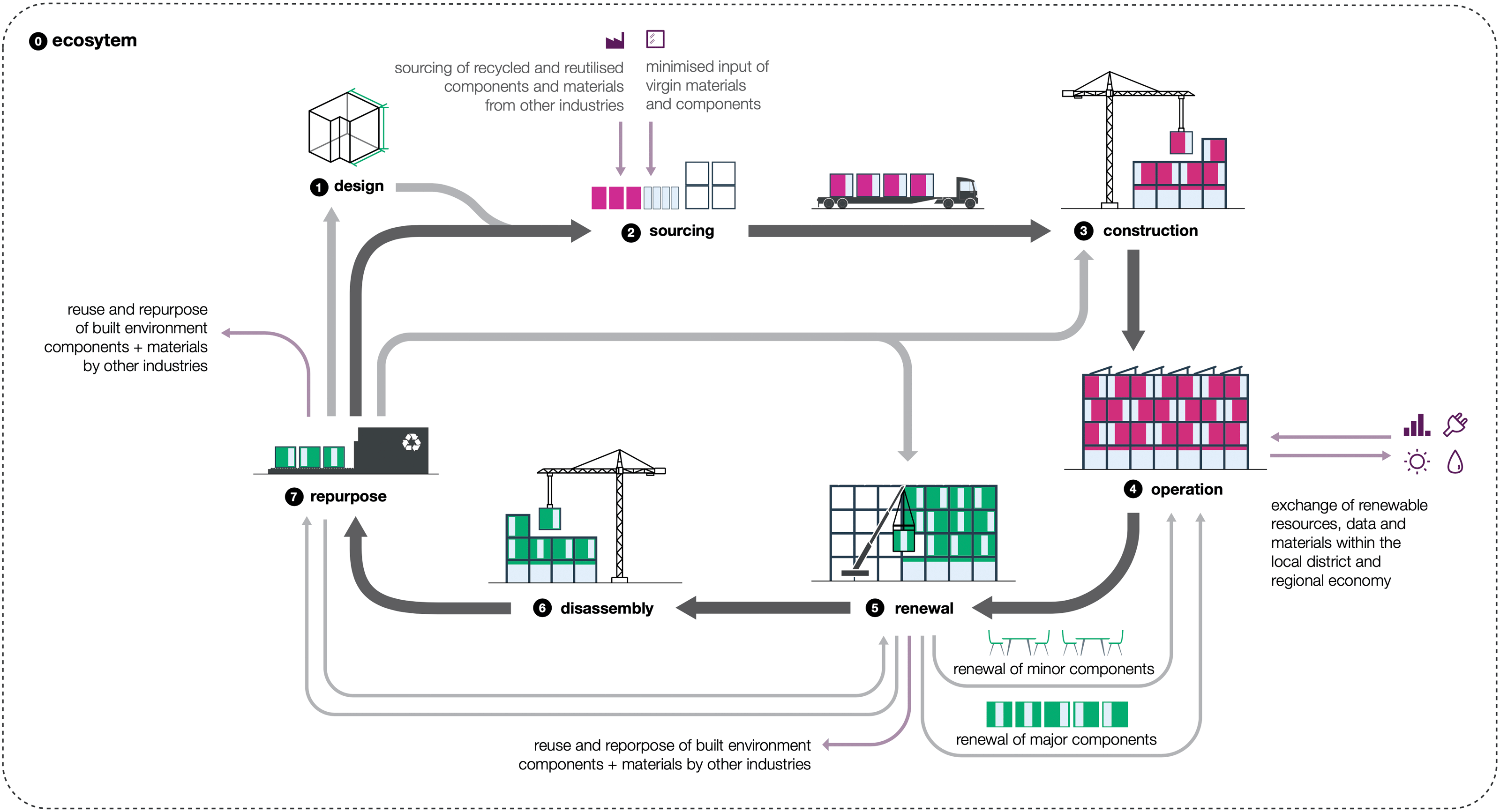

As the built environment contributes to almost 50% of the Worlds CO2 emissions it is the one sector where the greatest impact can be made to slow down the global warming effect. The importance of embedded carbon is critical in addressing the challenges and as stated by an article by Skidmore, Owings and Merill a transition to almost entirely engineered wood could reduce the buildings carbon footprint by up to 75%. Not only is the use of virgin materials derived from wood or biomass a critical component in the transition but also the need to reduce and reuse materials in construction.

Engineered wood such as those developed and patented by Lignor address the reduced material consumption due to far greater material yields from the logs combined with greater strength to weight ratios enabling thinner but stronger building components working to the “more from less” principle. Additionally, compared to concrete, the potential for disassembly of engineered wood elements to be reused in new buildings is far easier and less energy intensive and disruptive as described in the circular built environment with engineered wood by Arup in 2016.

![]()

Green and REDD® means that Lignor is not only Green but Reduces Emissions from Deforestation and (land) Degradation. Learn More: UNFCCC REDD+

Lignor is Green because its products come from sustainable and fast-growing accredited & certified sustainably harvested timber. Moreover, Lignor products are carbon sequestrating grown from sustainable grown and harvested tree crops.

They can compete in price and performance with traditional construction materials. However, Lignor products are much Greener than high embodied carbon construction products such as steel and concrete responsible for about 8% of Man’s world’s Greenhouse Gas Emissions. Bricks are not far behind.